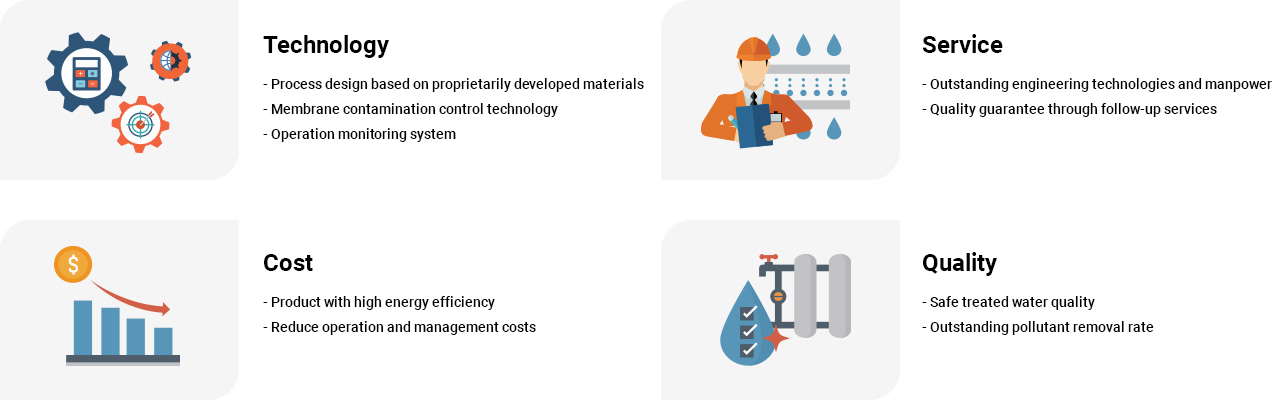

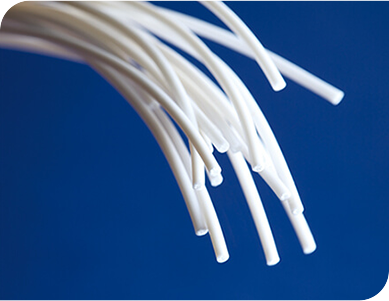

- Pollution resistance acquired by using PVDF material, which has high chemical resistance

- Produced in cutting-edge facilities to ensure excellent and uniform quality hollow fiber membrane

| Performance | |

|---|---|

| Water permeability (LMH/bar) | >400 |

| Tensile strength (kgf/fil) | >40 |

| Applied temperature (℃) | 1 – 40 |

| Applied pH | 2 – 10.5 |

| Features | |

|---|---|

| Material | PVDF |

| Type | Hollow Fiber Membrane |

| Inner/Outer diameter | 0.8 / 2.1 |

| Nominal pore diameter (㎛) | 0.03 |

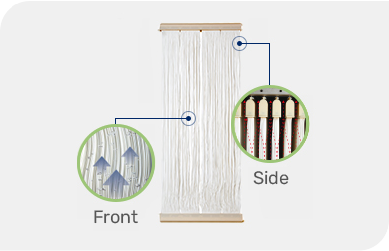

- Optimized airflow through module header thickness optimization

- Energy-saving products that maximize energy efficiency by smooth air flow

- Minimized operating pressure loss through an optimized flow design

- Improved membrane integration by efficient layout of cassette components

- Reduced maintenance cost by generating large air bubbles with small air volume and maximizing cleaning effect

- Uniform aeration effect within cassette even with a low air flow rate

- Effective physical cleaning and stable operation even in high integration of membrane modules

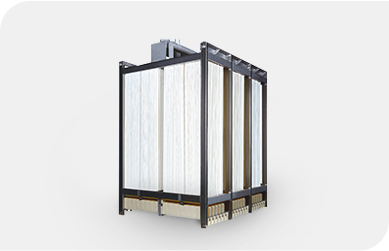

- Efficient and stable membrane process operation through proven operation sequence and control logic

- Operational convenience through automated backwashing and washing system

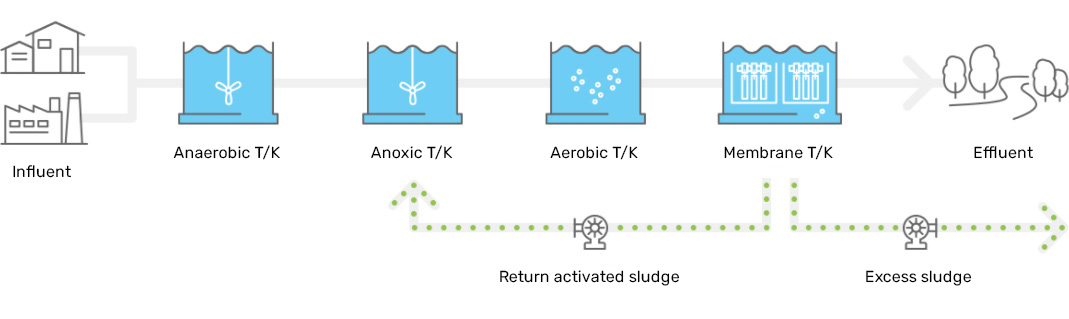

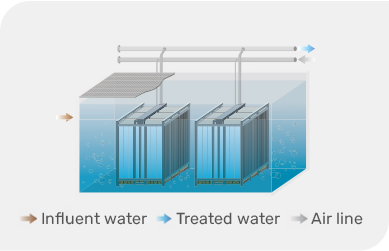

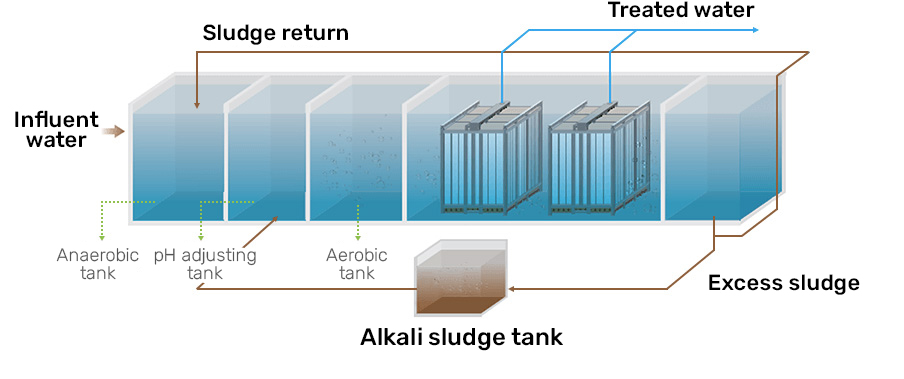

Nitrogen phosphorus treatment using sludge treated with sodium hypochlorite (NaOCl) and submerged membrane

Alkali sludge manufactured with activated sludge and injected into a bioreactor to improve the treatment efficiency of organic matter and T-N

Sewage treatment using membranes to treat T-P without coagulant injection

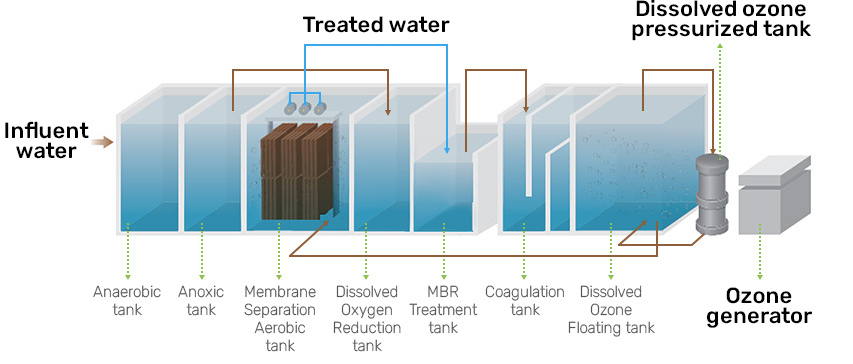

Technology that reduces energy use of the MBR process by applying a separator module and induction furnace for inducing slug flow

Removal of residual phosphorus and refractory materials and recovery of ozone into the aerobic tank in the integrated dissolved ozone flotation process of the later stage flotation and oxidation

Advanced sewage treatment technology that reduces membrane contamination through additional oxidizing effect of organic substances

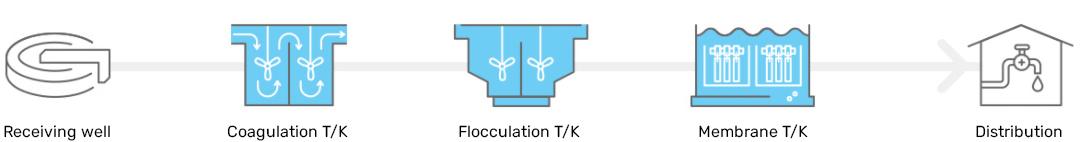

| MAIN APPLICATION | Sewage & Wastewater Treatment | Water Treatment | ||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MODULE | MODEL | SHU-1034 | SHU-2011 | SHU-2020 | SHU-2024 | SHU-3016 | SHU-3028 | SHU-3034 | ||||||||||||||||||||||

| TYPE | Supported Hollow Fiber | Supported Hollow Fiber | ||||||||||||||||||||||||||||

| Membrane Surface Area | ㎡ | 33.8 | 11.0 | 19.6 | 23.8 | 15.7 | 28.0 | 33.8 | ||||||||||||||||||||||

| Dimension | Length | mm | 845 | 852 | 852 | 852 | 852 | 852 | 852 | |||||||||||||||||||||

| Width | mm | 50 | 33 | 33 | 33 | 41 | 41 | 41 | ||||||||||||||||||||||

| Height | mm | 2,156 | 1,110 | 1,820 | 2,150 | 1,110 | 1,820 | 2,150 | ||||||||||||||||||||||

| Operating Conditions |

Max. Temp | ℃ | 40 | 40 | ||||||||||||||||||||||||||

| pH Range | - | 5 ~ 9.5 for Operation 2.0 ~ 10.5 for Cleaning |

5 ~ 9.5 for Operation 2.0 ~ 10.5 for Cleaning |

|||||||||||||||||||||||||||

| TMP Range | bar | -0.5 ~ 0.5 | -0.8 ~ 0.8 | |||||||||||||||||||||||||||

| ETTE | MODEL | SHU-B48M | SHC-C20M | SHC-R26M | SHC-S13M | SHC-S26M | SHC-S78M | SHC-C20W | SHC-R26W | SHC-S13W | SHC-S26W | SHC-S78W | ||||||||||||||||||

| Max. No. of Modules | ea | 48 | 20 | 26 | 13 | 26 | 78 | 20 | 26 | 13 | 26 | 78 | ||||||||||||||||||

| Max. Membrane Area | ㎡ | 1,621.9 | 220.0 | 510.4 | 309.4 | 618.8 | 1,856.4 | 313.5 | 729.1 | 439.3 | 878.5 | 2,635.5 | ||||||||||||||||||

| Dimension | Length | mm | 2,110 | 1,200 | 1,752 | 950 | 1,752 | 2,140 | 1,200 | 1,752 | 950 | 1,752 | 2,140 | |||||||||||||||||

| Width | mm | 1,745 | 1,000 | 740 | 750 | 740 | 1,752 | 1,000 | 740 | 750 | 740 | 1,752 | ||||||||||||||||||

| Height | mm | 2,535 | 1,560 | 2,140 | 2,560 | 2,560 | 2,560 | 1,560 | 2,140 | 2,560 | 2,560 | 2,560 | ||||||||||||||||||

| Connection | Permeate | ea | 6” × 1 | 2” × 1 | 3” × 2 | 3” × 1 | 3” × 2 | 6” × 1 | 2” × 1 | 3” × 2 | 3” × 1 | 3” ×2 | 8” ×1 | |||||||||||||||||

| Air | ea | 3” × 2 | 2” × 2 | 2” × 1 | 1.5” × 1 | 2” × 1 | 3” × 1 | 2” × 1 | 2” × 1 | 1.5” × 1 | 2” × 1 | 3” × 1 | ||||||||||||||||||